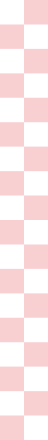

Applications such as CNC machines, press machines, packaging and filling lines used in industrial automation systems involve continuous, repetitive, and high-precision movements. Improper routing of power and signal cables used in these systems can lead to cable breakage, production downtime, and increased maintenance costs. At this point, moving cable carrier systems play a critical role in ensuring the safe and efficient operation of automation lines.

Plastic moving cable carrier solutions developed by Mitex enable cables to move with a controlled bending radius in automation systems. Cables operating along linear axes in CNC machines can be used for a long service life without wear or breakage thanks to moving cable channels. This both increases machine performance and prevents unplanned downtime.

In automation projects, suitable solutions for different operating conditions can be provided by selecting open, semi-closed, and closed series moving cable carrier systems. Mitex cable carrier systems offer reliable cable management that supports production continuity in automation lines.